Manufacturing Facility

RV infratech is a top steel manufacturer and specializes in PEB manufacturing and PEB supply, along with PEB Design, PEB Construction and PEB Erection, aiming for a sustainable future with steel structures. RVIS has more than 10000 MT/Year capacity state-of-the-art fabrication, cold forming & machining facility by using latest technology and machines at our sampla plant Located in ,Haryana, 50,000 sq.ft. (covered area) state -of - the -art workshop is equipped with the latest generation of production machines. Our capacity to execute the entire process in - house, helps us generate cost and time benefits for our clients. It also helps us to meticulously control the quality of material and the production process. We are equipped with latest computer software conforming to Indian / international standards. Experienced engineers and technicians oversee every phase of the design and manufacturing process and ensure emphasis on stability, endurance and aesthetics while ensuring optimum utilisation of steel.

Manufacturing is the value-added process and art of metalworking that involves the building of structures by cutting, shaping, hole-making, assembling, hot rolled sections, tubular sections, and welding of refined metal before they are loaded and taken to the site for their application.

Once the detailed drawings are obtained from the engineering offices, extensive metal preparation is carried out. Once the metal is ready, our machines are programmed with the appropriate values for the different parameters as per the requirement and application.

The formed and machined parts are then assembled and welded into place to form the final structure before being checked for accuracy. The product/structure is then shot blasted (as per SA 2 or SA 2.5 standards) and painted based on the required specifications.

Facilities

| 30,000 sq. ft. Plant Covered Area. |

| 20,000 sq. ft. open Area for Finished Good Storage |

| Shop Equipped with all related machines (List of machinery given below). |

| 10000 MT per annum Production capacity (site fabrication extra). |

| 7 EOT & hydra cranes & handling equipment. |

| Dedicated in-house Tool Room |

| Skilled Manpower & Engineers |

| Qualified and Experienced Erection Team. |

| Steel Stocking areas. |

| Store for consumables &misc items. |

| Double storey well furnished office complex. |

| Staff Quarters |

Design facility

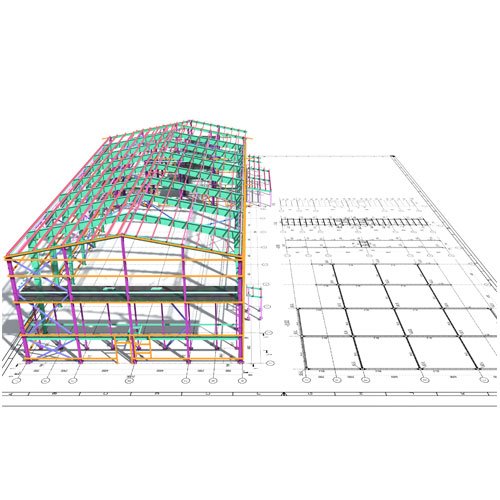

We call this "Knowledge Hub" — a world class design & engineering office manned with team of experienced Design & Engineers professionals and equipped with latest sophisticated design softwares.

Stadd — Pro, MBS, STRUCAD, MS Projects are among the few design and detailing tools are in use at SSIPL design & engineering center, thus delivers the quick, accurate and cost effective solutions. The design office offer intelligent engineering solutions and support pre & post order functions with arrangement, fabrication & erection drawings. The computerised drafting & detailing simplify manufacturing programs and erection methods. SSIPL knowledge archives has variety of design codes such as AISC, MBMA, AWS, UBC, ASCE, IBC, IS and many others to suit customer need of a pre-engineered building at anywhere in the world. The buildings are designed as per universal codes like AISC/ IS as per utility of the building in consultation with the client/ consultant. RV Infratech consistent efforts in research & developments has positioned the organisation as a lead runner in introducing innovative ideas and products in market place.

| Package | Design Detail | Code |

|---|---|---|

| STAAD.ProV8i | Design of Built-up & Hot rolled sections | IS 800 : 2007 LSD/WSD AISC ASD /LRFD |

| IS 800 : 1984 WSD | ||

| MBS software | Design of Pre-Engineered Buildings | AISC & IS 800 : 2007 |

| Master Series | Design of Composite Mezzanine Floor |

IS : 800 |

| Design of Cold form sections | IS : 801 |

The drafting office utilizes the following software packages :

| Packages | Usage |

|---|---|

| TEKLA–21 | 3D Modelling, Generating of GA & Fabrication drawings |

| AutoCAD-2015 | Preparation of GA & Fabrication drawings |

| Metal Building System (MBS) | Preparation of GA & Fabrication drawings |